Read navigation

- Chapter 1: Deep Dive: The Root Challenge of Traditional Casting Defects

- Chapter 2: 3D Printing: A Revolutionary Breakthrough from Technology to Solution

- Chapter 3: SANTI TECHNOLOGY: A Digital Engine to Empower the Foundry Industry

- Chapter 4: Looking to the future: digitalization and sustainability in the foundry industry

Chapter 1: Deep Dive: The Root Challenge of Traditional Casting Defects

1.1 Common casting defects and their deep causes

Casting defects are the direct cause of high scrap rates. These defects are not accidental, but are dictated by the physical and process limitations inherent in conventional casting processes.

firstlystomatogether withshrinkage. Porosity mainly originates from the involvement or inability to effectively discharge gases (e.g. hydrogen, mold outgassing) in the liquid metal during the pouring and solidification process. When the dissolved gases in the liquid metal are released due to reduced solubility during cooling and solidification, bubbles will form inside or on the surface of the casting if they are not discharged in time. Related to this is shrinkage, which is a natural phenomenon of volume contraction of the metal during solidification. If the cooling system is not properly designed, resulting in local mold temperature is too high, or insufficient complementary shrinkage, it will form internal voids or depressions, the so-called shrinkage holes.

Next.sandwichedtogether witherror type (math.). In conventional sand casting, sand molds and sand cores usually need to be assembled and bonded after being made from multiple pieces separately. In this process, any tiny rupture of the sand core or improper bonding may lead to sand particles being caught in the metal liquid, forming sand entrapment defects. In addition, if the mold parting surface or the sand core is not positioned accurately, it may also lead to the casting of the upper and lower parts of the misalignment of the mis-shape defects.

endcold storagetogether withcrackles. When the fluidity of the metal liquid is poor, the pouring temperature is too low, or the runner design is narrow, the two metal streams are solidified without being fully integrated at the leading edge, leaving a weakly connected cold segregation. And during cooling and solidification, if there are uneven stresses within the casting, thermal cracks may occur during shrinkage.

1.2 The traditional mold manufacturing "high cost" and "low efficiency" dilemma

Another core pain point of the traditional casting process is its mold manufacturing process. Traditional wood or metal core box manufacturing is a labor-intensive, highly skilled worker-dependent process with long lead times and significant costs. Any minor design change means that the mold needs to be rebuilt, resulting in high additional costs and weeks or even months of waiting time.

This over-reliance on physical molds also fundamentally limits the design freedom of castings. Traditional mold-making processes are unable to mold complex internal runners and hollow structures in one piece, which must be disassembled into multiple independent sand cores and then assembled by complex tooling and labor. 2. This process limitation forces designers to compromise and sacrifice part performance for manufacturability, such as simplifying cooling channels to accommodate drilling processes that do not allow for optimal cooling.

To summarize, the high scrap rate of traditional casting is not an isolated technical problem, but a product of its core processes. The traditional "physical trial and error" mode makes the foundry in the discovery of defects, need to go through a long process of mold modification and retesting, which is a high-risk, inefficient cycle. 3D printing's revolutionary value is that it provides a "moldless" solution, fundamentally reshaping the entire production process, will be the traditional "physical trial and error" mode, will be the traditional "physical trial and error" mode, will be the traditional "physical trial and error" mode, will be the traditional "casting" high scrap rate is not an isolated technical problem, but its core process products. The revolutionary value of 3D printing is that it provides a "moldless" solution that fundamentally reshapes the entire production process, transforming the traditional "physical trial-and-error" model into a "digital simulation validation" that puts the risk in front of the process, thus eliminating most of the causes of scrap at the source.

Chapter 2: 3D Printing: A Revolutionary Breakthrough from Technology to Solution

2.1 Moldless production: eliminating the root causes of obsolescence

The core advantage of 3D printing is its "moldless" production method, which allows it to bypass all of the mold-related challenges inherent in traditional casting, thus radically reducing scrap rates.

Directly from CAD to sand mold. Binder Jetting in Additive Manufacturing is the key to making this happen. It works by precisely spraying liquid binder onto thin layers of powder (e.g. silica sand, ceramic sand) from an industrial-grade printhead based on a 3D CAD digital model. By bonding layer by layer, the 3D model in the digital file is constructed in the form of a solid sand mold or sand core. This process completely eliminates the need to rely on physical molds. Because there is no need for lengthy mold design and manufacturing, the mold-making cycle can be shortened from weeks or even months to hours or days, enabling "print-on-demand" and rapid response to design changes, dramatically reducing up-front investment and trial-and-error costs.

One-piece molding and complex structures. 3D printing's layered manufacturing approach gives unprecedented design freedom. It is able to mold complex sand cores that would traditionally have to be split into multiple parts, such as the meandering runners inside an engine, into a single monolithic piece. Not only does this simplify the casting process, but more importantly, it completely eliminates the need for core assembly, bonding and misalignment, thus eradicating common defects such as sand entrapment, dimensional deviations, and misshaping caused by such issues.

2.2 Optimization process: data to guarantee casting quality

The value of 3D printing goes beyond "moldlessness" itself. It elevates the manufacturing process to a whole new digital dimension, allowing data to be verified and optimized before physical manufacturing, turning "after the fact" into "before the fact".

Digital Simulation and Design. During the digital design phase prior to 3D printing, engineers can use advanced Finite Element Analysis (FEM) software to perform accurate virtual simulations of the pouring, make-up shrinkage and cooling processes. This makes it possible to anticipate and correct potential defects that could lead to porosity, shrinkage or cracks before actual production. For example, by simulating the flow of the liquid metal in the runners, the design of the pouring system can be optimized to ensure smooth filling and effective venting. This digital foresight greatly improves the success rate of the first trial run and guarantees casting yields at the source.

Excellent sand properties. 3D printed sand molds, due to their layer-by-layer construction, can achieve uniform densities and air permeability that are difficult to achieve with traditional processes. This is crucial for the casting process. Uniform gas permeability ensures that gases generated inside the sand mold can escape smoothly during the pouring process, significantly reducing porosity defects caused by poor venting.

Cooling with shape. Conformal cooling technology is another revolutionary application of 3D printing in the field of casting molds. Mold inserts manufactured through metal 3D printing have cooling runners that can be designed to exactly mimic the surface contours of the casting. This achieves fast, uniform cooling, significantly reducing deformation and shrinkage due to uneven shrinkage, thus dramatically reducing the scrap rate. According to data, molds with follow-through cooling can reduce injection cycle times by as much as 70%, while significantly improving product quality.

From "physical trial and error" to "digital foresight". The core contribution of 3D printing is to transform the traditional foundry model of "trial and error" into "anticipatory manufacturing". It enables foundries to perform numerous iterations in a digital environment in a cost-effective manner, which is a fundamental shift in mindset and business process. This "hybrid manufacturing" model makes 3D printing easier to adopt by traditional foundries and enables the most efficient production. For example, 3D printing can be used to create the most complex and error-prone sand cores, and then combined with sand molds made using traditional methods to "build on the strengths".

Chapter 3: SANTI TECHNOLOGY: A Digital Engine to Empower the Foundry Industry

3.1 Core equipment: "hard power" for casting innovation

As a pioneer and leader in the field of additive manufacturing in China, 3DPTEK provides strong "hard power" support for the foundry industry with its self-developed core equipment.

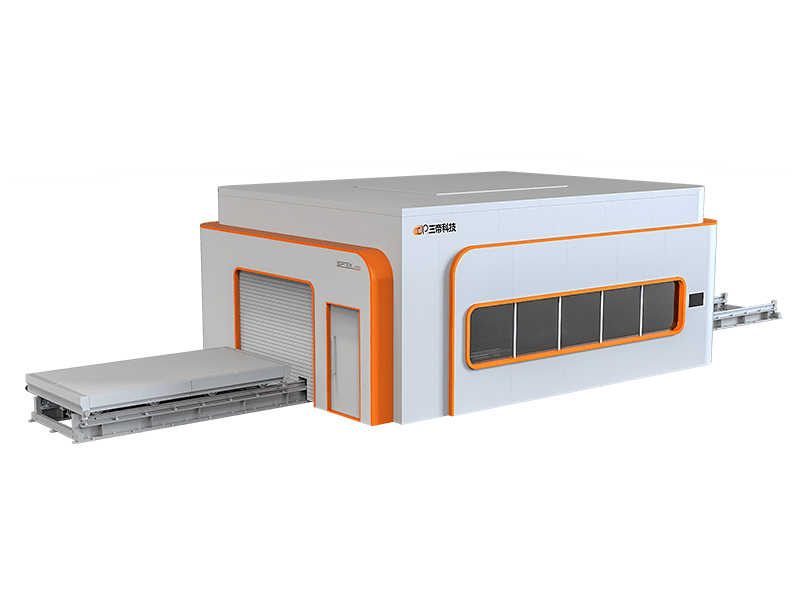

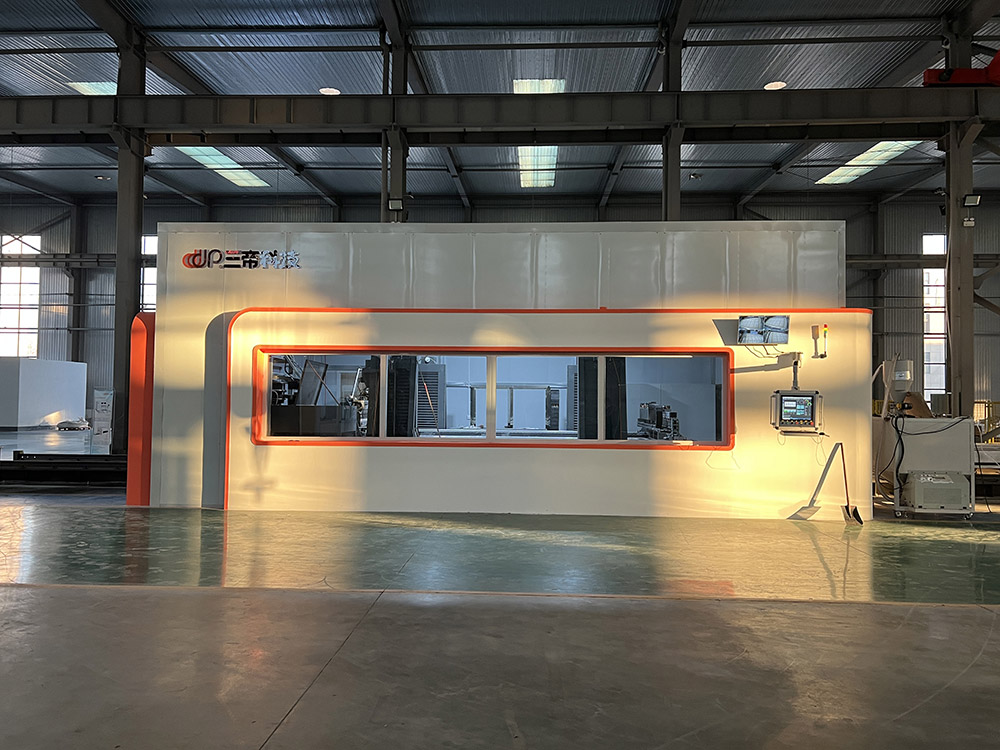

The company's core product lines are3DP Sand Printerthat highlights its leadership in technology. Flagship devices3DPTEK-J4000With an extra-large molding size of 4,000 x 2,000 x 1,000 mm, it is highly competitive on a global scale. This extra-large size allows large, complex castings to be molded in one piece without the need for splicing, further eliminating potential defects caused by splicing. At the same time, for example

3DPTEK-J1600PlusDevices such as these offer high accuracy of ±0.3 mm and efficient printing speeds, ensuring that superior quality is achieved while producing quickly.

In addition, SANTI Technology'sSLS (Selective Laser Sintering) Equipmentseries, such asLaserCore-6000The machines are also excellent in the field of precision casting. This series of equipment is particularly suitable for the manufacture of wax molds for investment casting, providing a more accurate solution for high-end, fine parts in aerospace, medical and other fields.

It is worth mentioning that SANDI Technology is not only an equipment supplier, but also an expert in material and process solutions. The company has developed more than 20 binders and 30 material formulations, compatible with cast iron, cast steel, aluminum, copper, magnesium and other casting alloys. This ensures that its equipment can be seamlessly integrated into a wide range of casting applications, providing customers with comprehensive technical support.

3.2 All-link services: integrated casting solutions

The competitive advantage of SANDI Technology lies not only in its hardware, but also in the integrated solutions it provides along the whole chain. The company has a strong "Trinity" innovation system - "research institute + post-doctoral workstation + R&D team". This model ensures continuous technology iteration and innovation momentum, and its accumulation of more than 320 patents is a strong proof of its technological leadership.

The company offers a "one-stop" turnkey service from design and 3D printing to casting, machining and inspection. This vertically integrated model greatly simplifies the customer's supply chain management, reduces communication costs and risks, and allows the foundry to focus on its core business.

3.3 Classic Case: Data-Driven Proof of Value

Successful cases are the most persuasive tool to convince potential customers. Through a series of real-world projects, SANDY Technology has quantified the significant business value that 3D printing technology brings.

in order toAutomotive water-cooled motor housingAs an example, this case perfectly demonstrates how the 3DP sand casting process solves the one-piece molding problem of "large size, thin wall, complex spiral cooling channels". 21. The successful application of this technology in the field of new energy vehicles has proved its significant advantages in the production of high-performance, complex structure castings.

On the otherIndustrial pump bodyIn the case of SANDI, SANDI adopted the hybrid manufacturing model of "3DP outer mold + SLS inner core". This complementary strategy shortened the production cycle by 80%, and at the same time improved the dimensional accuracy of the castings to CT7 level, which perfectly proved the powerful effect of the hybrid manufacturing mode.

The joint venture project with Xinxin Foundry provides the strongest business argument. By introducing 3D printing technology, the foundry achieved a turnover increase of 1,35%, doubled its profitability, halved its lead time and reduced its costs by 30%. This series of quantitative data provides irrefutable proof of the return on investment of 3D printing technology in the foundry industry.

The following table visualizes how 3D printing can address the pain points of the foundry industry on both a technical and business value level:

| Casting defects or pain points | Causes and limitations of traditional crafts | 3D Printing Solutions and Value |

| stoma | Poor mold venting; liquid metal entrapped in gas | Uniform, controlled sand permeability; digital simulation optimizes pouring system |

| shrinkage | Uneven cooling; inadequate retraction | Predictive optimization by numerical simulation; uniform cooling by shaped cooling channels |

| Sandwich, Mis-shape | Multi-core assembly, bonding and misalignment; parting face fit errors | One-piece molding of complex sand cores eliminates assembly; no physical parting surfaces required |

| High molding costs | Requires physical molds, highly skilled labor, long lead times | Mold-less production; print directly from CAD files, manufacture on demand |

| Inefficiency and long lead times | Long mold making; repeated trial and error | Reduced cycle time of 80%; rapid iterative design possible; print on demand |

| Increased business value | Low margins and erratic delivery | Turnover up 1,35%, margins doubled; costs down 30% |

Chapter 4: Looking to the future: digitalization and sustainability in the foundry industry

3D printing technology is leading the foundry industry from the traditional "manufacturing" to "smart manufacturing" fundamental transformation. According to the relevant report, the scale of China's additive manufacturing industry continues to grow at a high rate, and in 2022 it will exceed RMB 32 billion. This data clearly shows that digital transformation has become an irreversible industry trend.

In the future, 3D printing will be deeply integrated with artificial intelligence (AI), IoT and other technologies to achieve full automation and intelligent management of production lines. Foundries can use AI algorithms to optimize casting parameters and IoT sensors to monitor the production process in real time, thus further improving yield rates and production efficiency.

In addition, the unique advantages of 3D printing in realizing complex lightweight design will help automotive, aerospace and other downstream industries to improve product performance and reduce energy consumption, which is a perfect fit for the requirements of global sustainable development. 3D printing's on-demand production mode and extremely high material utilization (can be recycled more than 90% unbonded powder), also significantly reduces the generation of waste, for the casting industry to bring the environmentally friendly development path for the foundry industry.

concluding remarks 3D printing is not the end of casting, but its innovator. It gives the traditional foundry industry unprecedented flexibility, efficiency and quality assurance through its two core advantages of "moldless" and "digital". It enables foundries to free themselves from the plight of high scrap rates and enter a new era of greater efficiency, competitiveness and embrace of innovation. For any foundry seeking to stand out in a competitive market, embracing 3D printing technology, represented by SanDi Technology, is no longer an optional choice, but a necessary path to the future.

]]>Eliminating shrinkage holes has always been a complex challenge for foundries and engineers, with traditional methods often relying on experience and adjusting mold design, pouring systems and cooling processes through trial and error . However, with the advent of additive manufacturing technologies, especially industrial-grade sand 3D printing, casting design and production have been revolutionized, providing unprecedented new ways to completely solve shrinkage problems.

1. Root causes of casting shrinkage: geometrical limitations of conventional molds

To understand how 3D printing solves problems, it is first necessary to deeply analyze the pain points of traditional casting. The main reasons for shrinkage formation can be attributed to two things:

- Compensate for shrinkage deficiencies: As a casting solidifies and shrinks, it needs to be constantly replenished with liquid metal through the pouring system and riser. If the replenishment channels are not properly designed or are insufficient, the liquid metal cannot be transported to the areas most in need of replenishment, resulting in the creation of voids. ?

- Uneven solidification: If the cooling rate of different areas of the casting is not consistent, the heat is difficult to effectively disseminate, the formation of hot joints (hot spot). These hot spots are the last solidified areas, when the surrounding metal has solidified, they lack the liquid metal supplement, very easy to form shrinkage holes. ?

In conventional casting, molds and cores are manufactured with physical tools whose geometry is limited by machinability and releaseability. For example, the holes drilled for cooling water paths can only be straight lines. . This makes it difficult for engineers to design complex, curved make-up shrinkage channels or follow-through cooling channels inside the mold to precisely control the solidification process, thus increasing the risk of shrinkage defects The

2. 3D printing solutions: freedom of design to give "life" to molds and dies

The core strengths of industrial sand 3D printers areDesign Freedomcap (a poem)No mold productionIt prints sand molds and cores layer by layer directly from 3D CAD files. . This characteristic radically breaks through the geometric limitations of conventional processes and provides several powerful means of eliminating shrinkage as follows:

Option 1: Optimize the fill and contraction channel, precise infusion

Using 3D printing technology, engineers can design the optimal make-up shrinkage system inside the mold without having to consider machinability.

- Integrated pouring system: Traditionally, the sprue system (including the sprue and riser) has to be fabricated and assembled separately. 3D printing allows the entire sprue system, the filler riser and the mold itself to be printed in one piece. This integrated design ensures a seamless connection and precise alignment of the channels, greatly reducing the risk of shrinkage failure due to assembly errors. ?

- Design of precise filler risers: 3D printing allows the precise design and printing of shrinkage risers above the hot joint areas of the casting, ensuring a constant flow of molten metal to fill the void created by solidification shrinkage. It has been shown that overflow risers above the casting can effectively vent gases, thus reducing porosity defects in the casting. ?

- Eliminate undercutting and complex structural barriers: In traditional processes, complex undercuts and internal passages require multiple cores to be assembled, which not only increases assembly errors, but can also easily lead to dislodged or misaligned cores. 3D printing allows multiple individual cores to be combined into a single, complex, integrated core, eliminating the need for assembly altogether, and improving the accuracy and quality of the casting. ?

Option 2: Conformal cooling for uniform solidification

For the molds themselves, 3D printing can be equally revolutionary. ByConformal cooling(conformal cooling) technology, which allows the design of cooling channels inside the mold that match the surface contour of the casting. The

- Principle: Conventional cooling channels are drilled in straight lines and do not cover all the areas that need to be cooled, resulting in uneven temperatures in the mold . Conformal cooling, on the other hand, uses 3D printing to integrate curved, serpentine cooling waterways into the mold so that they fit snugly on the surface of the casting . ?

- Advantage: This design results in more uniform cooling and significantly reduces the risk of localized overheating of the mold. A more balanced temperature gradient means that the solidification process is more controlled, radically reducing the formation of hot joints and thus preventing shrinkage. It has been demonstrated that the use of a form-following cooling mold reduces the temperature variation during mold cooling to as low as 18°C, thus significantly reducing the risk of casting warpage. ?

Scenario 3: Digital Simulation and Rapid Iteration to Prevent Problems Before They Happen

The digital workflow of 3D printing provides engineers with valuable opportunities for "trial and error" before going into production. The

- Casting simulation software: Engineers can use casting simulation software (e.g. Cimatron) to simulate the flow and solidification of molten metal. If the simulation results show a risk of shrinkage, the mold design can be quickly adjusted, e.g. by changing the location of the sprue or riser, and then tested virtually again. ?

- Rapid prototyping and iteration: If a physical prototype is required, 3D printing can print a mold or core in hours or days. This allows engineers to iterate and validate designs multiple times at a fraction of the cost and speed. This agile development model is unimaginable in traditional casting, which requires expensive mold making and long waiting times. ?

3. Not just eliminating defects, but a leap in efficiency

The use of 3D printing technology to solve the problem of casting shrinkage, bringing not only the improvement of product quality, but also a series of chain of business value:

- Reduce costs: 3D printing significantly reduces production costs by eliminating the expensive physical mold and tooling manufacturing aspects . According to research, 3D printing can save up to 50%-90% compared to traditional methods . ?

- Shorten the delivery time: Mold making time has been reduced from weeks or even months to hours, allowing companies to respond more quickly to market demands . In one case, a company was able to reduce lead times by 9 weeks by using a sand 3D printer. ?

- Reduce scrap rates: The accuracy and consistency of the molds have been greatly improved, reducing casting defects due to human error or mold wear, thus significantly reducing scrap rates. ?

- Simplify the process: Consolidating multiple parts into a single integrated component simplifies complex assembly processes and reduces reliance on highly skilled labor. ?

Conclusion: 3D printing - a "cure" for the foundry industry

Casting shrinkage is not an isolated technical problem, but the traditional casting process in the face of complex design and high-precision requirements of the systematic challenges exposed. Industrial sand 3D printers, with their unique technological advantages, offer a "cure" for the problem at its source. It eliminates the risk of shrinkage by giving engineers unprecedented design freedom, enabling them to build optimized internal structures and cooling systems. The

For the pursuit of excellent quality, efficient production and cost optimization of modern foundry enterprises, 3D printing is no longer dispensable "additional options", but to promote industrial upgrading, in the fierce competition in the market to win the first chance of the key technology. It is not just a piece of equipment, but also to the "digital casting" bridge to the future, so that the former "casting problems" to be solved! The

]]>I. Equipment selection strategy based on casting size

The size of the casting is a central factor in determining the specification of a sand 3D printer, which needs to be selected with a balance between current needs and future developments:

- Statistical analysis of existing casting dimensions

- Enterprises need to comprehensively sort out the past 1-2 years of casting orders, categorized by product type (such as automotive parts, aviation structural components, pumps and valves shells), statistics on the length, width and height of each type of casting size range, drawing size distribution histogram. For example, an automobile foundry statistics found that 60% engine block castings in 300-500mm in length, width 200-350mm, height 150-250mm;

- Identify the "core size range" with the highest percentage and use it as a basis for filtering printers. As in the case above, 3DPTEK's 3DPTEK-J1800(molding size 1800×1200×1000mm) can easily cover most of the engine block sand printing needs, to avoid "small horse-drawn cart" (equipment molding size is too large, waste of equipment space and printing costs) or "too big to use" (equipment) (equipment molding size is not enough to print large castings).

- Considering future business expansion

- Combined with the enterprise's market planning for the next 3-5 years, new product development plan, prejudge the casting size changes that may be involved. If you plan to develop the wind power equipment castings business, you need to investigate in advance the size of wind power hubs, blades and other large castings (wind power hub diameter of up to 3-5 meters), to reserve enough space for equipment upgrades;

- If large castings are only occasionally undertaken, consider 3DPTEK's 3DPTEK-J4000 Ultra-large size printer (maximum molding size 4000×2000×1500mm), or "sand cut block + combined assembly" printing strategy (3DPTEK equipment supports localized printing, which facilitates the operation of the cut block), to reduce the cost of equipment procurement.

- Handling of special size requirements

- For castings with special dimensions such as extra-long, extra-wide, extra-thin, etc. (e.g., elongated shaft castings with an aspect ratio of more than 5:1, thin-walled parts with a thickness of less than 5mm), it is necessary to examine the printing accuracy and stability of the equipment in addition to the molding dimensions. 3DPTEK's bonded injection technology ensures that the molding of special-sized castings is performed with a high degree of precision of ±0.3mm, thus avoiding the scrapping of castings due to deviations in dimensions. avoid scrapping the castings due to dimensional deviation.

Second, suitable for the casting material equipment parameters selection

Different casting materials (e.g. cast iron, cast aluminum, cast steel) have different requirements for sand strength, air permeability and gas generation, which need to be matched with the corresponding equipment parameters and material technology:

- Material properties and sand demand analysis

- Cast iron parts: due to the good fluidity of iron and moderate solidification shrinkage, the strength of the sand mold is required to be high (tensile strength ≥ 0.8MPa) to prevent the sand mold from erosion and breakage during pouring. The high-strength furan resin binder matched with 3DPTEK equipment, together with silica sand, can meet the needs of sand mold printing for cast iron parts;

- Aluminum casting: Aluminum liquid solidification speed is fast, easy to absorb air, the sand type is required to have good air permeability (air permeability value ≥ 150) and low outgassing (outgassing ≤ 15ml/g), to avoid casting porosity defects. 3DPTEK's open-source material process can be adjusted according to the needs of the binder formula, suitable for ceramic sand, zirconia sand and other low outgassing, high air permeability sand, to meet the casting of aluminum casting sand print.

- Material compatibility and parameter adjustment

- The 3DPTEK sand 3D printer supports a wide range of casting sands (including quartz sand, pearl sand, chromite sand, etc.), allowing companies to choose sand materials flexibly according to casting materials and cost considerations. For example, when producing high-end stainless steel castings, zirconium sand (high temperature resistant and chemically stable) is used with 3DPTEK's special binder to improve the sand mold's anti-washout and anti-sticking properties;

- The nozzle parameters (e.g., orifice diameter, spraying frequency) and heating and curing parameters (curing temperature and time) of the equipment need to be precisely adjusted according to the characteristics of the sand material and the type of binder. For example, when using fine-grained quartz sand, it is necessary to reduce the diameter of the spray hole (e.g., from 0.3mm to 0.2mm) and increase the spraying frequency to ensure that the binder evenly covers the sand particles; for thermosetting binder, it is necessary to optimize the heating curing curve (e.g., increase the curing temperature from 150℃ to 180℃, and extend the curing time from 30 seconds to 45 seconds), so as to ensure that the strength of the sand pattern curing.

- New material application and technical support

- As the casting industry's demand for high-performance, lightweight castings increases, new types of sand materials (such as composite sand mixed with metal powders and nano-modified sand) are gradually being applied. 3DPTEK continues to research and develop new material processes that can be customized to meet the needs of enterprises and customize material solutions to help them quickly realize the application of new materials in sand printing.

Comprehensive Advantages of 3DPTEK Sand 3D Printers

- Full-size product matrix: 3DPTEK has a full line of sand 3D printers ranging from 1.6 meters to 4 meters in size, including 3DPTEK-J1600Pro,3DPTEK-J1600Plus,3DPTEK-J1800,3DPTEK-J1800S,3DPTEK-J2500,3DPTEK-J4000 A variety of models, such as to meet the different sizes of enterprises, different sizes of castings printing needs, to avoid enterprises due to the limitations of equipment specifications missed orders.

- open source material processIt supports users to adjust the binder and sand material formula as needed to reduce the material cost 20%-30%. At the same time, it is equipped with high-performance resin binder, curing agent and cleaning agent to ensure the stable quality of sand molding and solve the problems of material selection and process optimization of the enterprise.

- High-precision molding technologyThe company adopts piezoelectric inkjet technology, high-resolution inkjet system, and special binder formula to realize ±0.3mm high-precision printing, which effectively reduces the machining allowance of the castings, improves the quality of the castings and the production efficiency, and is especially suitable for aerospace, automotive and other industries with stringent requirements for precision.

- Flexible area molding without sand boxAs 3DPTEK-J4000 Innovative use of sandbox-free flexible area molding technology, support for local printing, can economically and efficiently realize the manufacture of oversized sand molds, compared with the traditional box printing, the equipment footprint is reduced by more than 30%, and the printing cost is reduced by 15%-20%.

Through the above selection strategy based on casting size and material, combined with the comprehensive advantages of 3DPTEK sand 3D printers, enterprises can accurately match the parameters of the equipment to achieve a high degree of compatibility between equipment performance and production needs, and at the same time improve the quality of castings, reduce production costs and enhance market competitiveness.

]]>工業級蠟模 3D 打印機:2025 年大型鑄造全指南,縮短 80% 周期 + 提升精度方案最先出現在三帝科技股份有限公司。

]]>I. What is an industrial-grade wax 3D printer? Core Definition + Comparison to Traditional Processes

Industrial-grade wax mold 3D printers are based onSelective laser sintering (SLS) TechnologyIt is an industrial machine for the production of high-precision wax molds made of casting wax powder / wax-like powder, which are fused layer by layer and can be used directly for lost wax investment casting. It has significant advantages over the traditional wax molding process and is especially suitable for large casting scenarios (part sizes above 500 mm):

| comparison dimension | Industrial Wax Mold 3D Printer | Traditional wax molding process (handmade / CNC) |

| production cycle | 3-7 days (large wax models) | 2-4 weeks |

| Dimensional accuracy | ±0.1mm | ±0.5-1mm |

| Complex structure realization | Easy printing of internal cooling channels, thin-walled honeycomb structures | Multiple sets of wax molds need to be disassembled and are prone to assembly errors. |

| labor cost | Automated printing, one person can operate multiple machines | Dependence on skilled tradesmen, high labor costs 300% |

| Material utilization | 90% above (unsintered wax powder recyclable) | 60%-70% (cutting / manual waste) |

| Design Iteration | CAD files can be reprinted within a few hours after modification. | Need to remake the mold, long cycle time |

The 4 core benefits of industrial-grade wax mold 3D printers for foundries (solving industry pain points)

1. Reduced cycle time 80% for fast response to order requirements

It takes 3 weeks to make a wax mold of a large automotive engine block using traditional processes, but an industrial-grade 3D printer can do it in just 3 days. An aerospace foundry used LaserCore-5300 to print a wax model of a turbine blade, from design to finished product in 48 hours, shortening 80% compared with the traditional process, and compressing the trial production cycle of a new product from 3 months to 1 month, thus seizing the first opportunity in the market.

2. 5 times higher accuracy and lower casting scrap rate

Industrial-grade wax mold 3D printer has an accuracy of ±0.1mm and surface finish Ra≤1.6μm, which can reduce the casting post-treatment process. Due to the large error of wax mold made by traditional process, the casting scrap rate is more than 15%; while the 3D printed wax mold reduces the scrap rate to below 5%, and a foundry produces large valve castings and reduces the loss of scrap by 800,000 RMB annually.

3. Breaking through structural limitations and realizing difficult casting

No need to consider "mold release" issues, allowing for designs not possible with conventional processes, especially for high-end manufacturing:

- Aerospace:Multi-layer cooling channels inside the turbine blades(The traditional process requires 5 sets of wax molds to be disassembled, while 3D printing molds the mold in one go, with no assembly errors);

- Cars:Engine block integrated runners(Reduced post-drilling process and increased fluid efficiency by 10%);

- Heavy machinery:Thin-walled honeycomb structure for large shells(Wall thickness as low as 2mm, weight reduction 20%, strength increase 15%).

4. Long-term cost reductions 40%, offsetting equipment investment

Despite the high initial investment ($50,000+) for an industrial-grade wax-molded 3D printer, the cost advantage is significant when calculated over the full lifecycle:

- Eliminate mold costs: Traditional large CNC wax mold mold costs over 200,000 yuan, 3D printing can be completely eliminated;

- Reduced labor costs: 1 person can operate 3 machines, reducing 80% labor compared to the traditional process;

- Reduction of scrap loss: precision improvement has reduced the casting scrap rate from 15% to 5%, saving more than 500,000 yuan in material cost per year.

Industrial Wax Mold 3D Printing Workflow: 6 Steps from Design to Wax Mold (for Large Casting)

The industrial wax 3D printing process is highly automated and does not require complex human intervention. The core steps are as follows (for example, wax molding of a large turbine blade):

- Digital Design and OptimizationThe 3D model of the wax mold is constructed in SolidWorks/AutoCAD, the shrinkage is reserved according to the casting metal properties (e.g. steel needs to be enlarged from 1%-2%), and the structure of the sprue and the vent is designed and exported as an STL format file;

- Device parameter settingLoad casting wax powder into a printer (e.g. LaserCore-6000) and set the parameters: layer thickness 0.08-0.35mm, laser power 55-300W, molding rate 80-300cm3/h to ensure that it is suitable for large wax models;

- automated printingAfter the equipment is started, the laser sinter the wax powder layer by layer according to the slicing trajectory. It takes 10-20 hours for a large wax model (e.g. 1050×1050×650mm) to be printed unattended at night without human intervention;

- Cleaning up after printingAfter the wax mold is completed, remove it from the molding chamber, blow off the excess wax powder on the surface with compressed air (this wax powder can be recycled directly), and inspect the wax mold for holes and cracks (the defect rate of 3D printed wax molds is less than 1%);

- Wax mold assembly (mass production)If batch casting is required, individual wax molds are attached to a "wax tree" to improve pouring efficiency;

- Suitable for lost wax castingThe wax mold is immersed in ceramic slurry to form a high-temperature-resistant ceramic shell, which is then burned in a 700-1000°C kiln to remove the wax mold (the ash content of the 3D printing wax mold is <0.1%, and the combustion is complete with no residue), and then the metal can be poured in.

How to choose industrial-grade wax 3D printers for foundries? 4 core selection criteria

1. Prioritizing molding space: adapting to the needs of large-scale casting

Large casting parts (such as automotive engine blocks, aerospace frames) with dimensions of 500-1000mm, need to choose the molding space ≥ 500 × 500 × 500mm model:

- For small and medium-sized foundries (part sizes 500-700mm): A model with a molding space of 700×700×500mm (e.g. LaserCore-5300) is available;

- Large foundries (part size 700-1000mm): We recommend a model with a molding space of 1050 x 1050 x 650mm (e.g. LaserCore-6000).

2. Technology Type Lock SLS: Ensuring strength and precision of wax molds

SLS technology sintered wax powder by laser, the wax molds have high density (≥0.98g/cm3) and high strength (flexural strength ≥15MPa), which can withstand the external force during ceramic paste coating and handling to avoid deformation. Wax molds made by other technologies (e.g. FDM) have low strength, are easily damaged and are not suitable for large-scale casting.

3. Focus on core parameters: accuracy, speed and material compatibility

- accurate: Choose a ±0.1mm model to ensure casting dimensions are met and to minimize post-processing;

- Molding rateThe priority is given to models with more than 200 cm3/h (e.g. AFS LaserCore-6000 up to 300 cm3/h) to increase the efficiency of the production of large wax molds;

- Material compatibility: A wide range of casting waxes (e.g. low ash casting waxes, high temperature waxes) are required to support the casting of different alloys (aluminum alloys, steel, titanium alloys).

4. Software and services: making the transition less difficult

- The software must be compatible with the main CAD formats (STL/OBJ) and come with casting simulation (optimization of the structure of the wax model and reduction of defects);

- Service providers need to provide full-process support: free operator training (to ensure that the operation is mastered within 3 days), equipment installation and commissioning, 24-hour after-sales response (domestic door-to-door service ≤ 24 hours).

V. 2025 industrial-grade wax mold 3D printer popular models recommended (suitable for different casting needs)

Based on industry feedback and actual application cases, the following 3 models in 2025 are outstanding in the large casting field, covering entry to high-end scenarios:

| models | Molding space (mm) | Type of technology | accurate | Molding rate | Applicable Scenarios | Core Advantages |

| AFS-500 (entry level) | 500 x 500 x 500 | SLS | ±0.1mm | 80-150cm3/h | Industrial tools, small and medium-sized castings (up to 500mm) | Cost-effective, low power consumption (15KW), suitable for small and medium-sized foundry trial production |

| LaserCore-5300 (mid- to high-end) | 700 x 700 x 500 | SLS | ±0.1mm | 150-250cm3/h | Aerospace turbine blades, automotive parts (500-700mm) | Rapid iteration, stable accuracy, suitable for multi-material printing |

| LaserCore-6000 (high-end) | 1050 x 1050 x 650 | SLS | ±0.1mm | 250-300cm3/h | Large automotive engine blocks, aerospace frames (700-1000mm) | Extra large molding space, high efficiency of mass production, suitable for high production foundries |

Model highlights analysis

- AFS-500Low entry cost, easy to operate, 1 person can manage multiple machines, suitable for small and medium foundries trying 3D printing for the first time, for small and medium-sized wax molds such as industrial tools, valves, and so on;

- LaserCore-5300The wax molds of turbine blades are widely used in the aerospace industry. The wax molds have a high surface finish and do not need to be polished, increasing the yield of the castings to more than 95%;

- LaserCore-6000The machine is one of the few in China that can print 1050mm wax models, and can nest 20 small and medium-sized wax models (e.g., automotive parts) in a single run, which increases the utilization rate of the machine by 60%.

Industrial Wax Mold 3D Printing Common Problems + Expert Solutions

1. High initial investment in equipment? -- Phased investment reduces risk

Small and medium-sized foundries can purchase entry-level models (e.g., AFS-500) for wax molding of high value-added parts (e.g., precision valves), quickly recoup their costs through high-margin orders, and then upgrade to higher-end models after 1-2 years.

2. Incomplete burning of wax molds leading to defective castings? -- Optimization of sintering and firing parameters

- When printing: Adjust the laser power (55-80W) to ensure that the sintered density of the wax mold is ≥0.98g/cm3 and to reduce the internal porosity;

- Firing: gradually increase the kiln temperature from 700°C to 1000°C and hold for 2-3 hours to ensure complete vaporization of the wax model (can be verified by the change in weight of the ceramic shell).

3. Wax powder recycling is difficult, material waste? -- Configure automated recycling system

By choosing the wax powder recycling equipment with automatic screening and drying function, the unsintered wax powder can be reused directly after treatment, and the material utilization rate is increased from 90% to more than 95%, which saves 200,000 yuan of material cost per year.

4. Unskilled team operation, affecting productivity? -- Give preference to "equipment + training" as an all-in-one service.

Choose a service provider that provides free training (such as AFS brand), 1 to 1 teaching operators to master the daily operation of the equipment, troubleshooting, to ensure the normal operation of the equipment.

VII. Conclusion: Industrial-grade Wax Mold 3D Printer, "Must-have Equipment" for Foundry Transformation

In the increasingly competitive large-scale foundry industry, "high precision, fast cycle time, low cost" has become the core competitiveness -- industrial-grade wax mold 3D printers help foundries break through the limitations of traditional processes by shortening the cycle time by 80%, increasing the accuracy by 5 times, and reducing the cost by 40% in the long run. to help foundries break through the limitations of traditional processes.

In 2025, the commercialization of models such as the LaserCore series will provide a fast track from design to wax mold for industries such as aerospace, automotive and heavy machinery. For foundries, choosing the right industrial-grade wax 3D printer will not only reduce costs and increase efficiency, but also unlock difficult casting orders and secure a place in high-end manufacturing - the core value of industrial-grade wax 3D printing in the future of the foundry industry.

工業級蠟模 3D 打印機:2025 年大型鑄造全指南,縮短 80% 周期 + 提升精度方案最先出現在三帝科技股份有限公司。

]]>4 米級大型砂型鑄造 3D 打印機:2025 年解鎖大型鑄件制造,縮短 80% 周期 + 降本方案最先出現在三帝科技股份有限公司。

]]>Read navigation

- First, the 4 major pain points of the traditional large-scale sand molding process, 4-meter 3D printing how to crack?

- Second, 4-meter-class large sand 3D printer core analysis: 3DPTEK-J4000 parameters and technical advantages

- The 5 core advantages of 4-meter sand 3D printing: directly enhancing enterprise competitiveness

- Fourth, 4-meter sand 3D printing 4 major industry application scenarios (with actual cases)

- Fifth, choose the right solution: 3DPTEK "equipment + ecological" integrated services

- Future Trends in Large-Scale Sand 3D Printing in 2025: Toward "Bigger and Smarter"

- Conclusion: 4-meter sand 3D printing opens a new era of large casting manufacturing

First, the 4 major pain points of the traditional large-scale sand molding process, 4-meter 3D printing how to crack?

Traditional large-scale sand mold manufacturing (size over 2 meters) needs to go through "mold making - sand core disassembly - manual assembly", there are difficult to solve the pain points, but 4-meter sand 3D printing through the "integrated molding + digital process" to achieve a comprehensive breakthrough. process" to realize a comprehensive breakthrough:

| Type of pain point | Status of traditional crafts | 4-Meter Sand 3D Printing Solution |

| long lead time | 4-8 weeks to produce a 4-meter sand mold (2-4 weeks for molding alone) | 2-5 days to complete the entire sand mold printing, full cycle time reduction 80% |

| Structural limitations | Complex internal channels, topology optimization structure requires more than 10 groups of sand cores to be disassembled, which is prone to assembly errors. | Print complex structures in one piece, no need to disassemble, error ≤ 0.3mm |

| high cost | Large metal molds cost over $500,000 and require 10 people/day for manual assembly. | No mold costs, automated printing reduces 80% labor |

| High scrap rate | Sand core splicing gaps lead to casting defects, scrap rate 15%-20% | Seamless sand molding + simulation optimization to reduce scrap rate to below 5% |

Second, 4-meter-class large sand 3D printer core analysis: 3DPTEK-J4000 parameters and technical advantages

1. Key parameters: meeting the full scenario requirements for large castings

3DPTEK-J4000 As a benchmark equipment in the industry, it is not a simple enlargement of a small printer, but an exclusive design for large-scale sand manufacturing with the following core parameters:

- Maximum molding size: 4000mm x 2000mm x 1000mm (can print the whole sand pattern of 4 meters long and 2 meters wide without splicing);

- Process Type: Inkjet binder injection (3DP), suitable for special casting sands such as quartz sand, ceramic sand and ceramic sand;

- Accuracy and Resolution: Dimensional accuracy ±0.3mm, nozzle resolution 400dpi, surface finish up to Ra6.3μm;

- Layer thickness and efficiencyLayer thickness can be adjusted to 0.2-0.5mm, and 2-3 sets of medium-sized sand patterns (e.g. 2-meter-long pump body sand patterns) can be printed in a single day;

- Material utilization: 100% of uncured sand recycled with less than 5% of material waste.

2. Core technology: "sand-free flexible area molding" cost reduction

Traditional 4-meter sand molding equipment needs to be fixed large sand box, a single print needs to be filled with tens of tons of sand, the cost is extremely high. And 3DPTEK-J4000 A breakthrough was achieved with the "Sandless Flexible Area Molding Technology":

- Eliminates the need for a fixed sand box, dynamically adjusts the sand bed area to the size of the sand pattern, and reduces the amount of 70% sand used;

- Elimination of large sanding box infrastructure investment (traditional sanding box cost more than 200,000 yuan);

- Equipment purchase cost is the same as 2.5-meter class equipment, with a 50% return on investment.

The 5 core advantages of 4-meter sand 3D printing: directly enhancing enterprise competitiveness

1. Shorter cycle time 80% to seize the market opportunity

It takes 6 weeks to make a 4-meter engine block sand mold by traditional process, but 3DPTEK-J4000 takes only 3 days to finish printing, and the whole cycle from design to casting delivery is compressed from 3 months to 1 month. A heavy machinery company used it to make large gearbox shell sand mold, new products on the market 2 months ahead of schedule, to seize a share of 30% market segment.

2. Achievement of "oversized + complex" integrated molding

No need to consider the constraints of "stripping" and "splicing" of conventional processes, making it possible to accomplish difficult designs:

- Aerospace: 4-meter-long turbine casing for theInternal multi-layer cooling channels(The traditional process requires 12 sets of sand cores to be disassembled, while 3D printing molds them in a single pass);

- Energy sector: 3-meter diameter wind turbine flangesTopology-optimized weight-reducing structures(Weight reduction 20%, strength increase 15%);

- In the field of industrial machinery: 4-meter-long pump bodies for theSpiral Worm Structure(No splicing seams, 8% increase in fluid efficiency).

3. Long-term cost reduction 40% with short payback period

Despite the high initial investment in the equipment, the cost advantage is significant when calculated over the full life cycle:

- Save mold cost: large castings need to replace 2-3 sets of molds per year, 3D printing can be completely eliminated, saving more than 1 million yuan per year;

- Reduce scrap loss: a foundry with its production of large valve sand mold, scrap rate from 18% to 4%, reducing annual losses of 500,000 yuan;

- Digital inventory: sand patterns are stored as CAD files, eliminating the need to stack physical patterns in the warehouse and saving 100 square meters of storage space.

4. Support "batch + customized" dual-mode production

The 4-meter molding space not only prints large sand molds, but also allows for the nested mass production of small parts:

- 200 small pump body cores can be nested in a single print run (traditional processes require batch production);

- Supports "1 set of large sand molds + batch of small sand cores" mixed printing, increasing equipment utilization by 60%;

- Fast response to customization needs, modifications to the design only require updating the CAD file, no need to recreate the mold.

5. Comply with environmental requirements and help green production

Global environmental regulations are tightening (e.g., China's "dual carbon" policy, EU carbon tariffs), and 4-meter sand 3D printing meets environmental needs through two major technologies:

- Use of low VOC binders (emissions below national standard 60%) to reduce air pollution;

- Sand 100% is recycled and reused, reducing solid waste emissions by more than 100 tons per year, which meets the requirements for green factory certification.

Fourth, 4-meter sand 3D printing 4 major industry application scenarios (with actual cases)

1. Automotive and commercial vehicle sector: core components for new energy trucks

- Application: 4-meter long new energy heavy truckIntegral motor housingThe sand molding of large engine block;

- Case in point: a car company uses 3DPTEK-J4000 Printing the sand mold of the motor shell, the cycle time is shortened from 4 weeks to 3 days, and the casting has no defects at the thin wall (2.5mm), realizing a weight reduction of 30% for the motor and a range increase of 100km.

2. Aerospace and defence: large lightweight structural components

- Application: 4 meters longAero-engine turbine casing, Missile Launcher Tank Sand Type;

- Advantage: integrated printing to avoid sand core splicing errors, casting dimensional accuracy up to CT7 level, to meet the aerospace "zero defect" requirements.

3. Industrial machinery and energy sector: core components for heavy equipment

- Application: 4 meters longLarge Pump Body Worm CasingThe sand molding of wind turbine gearbox shells with a diameter of 3 meters;

- Case: A heavy industry enterprise uses it to print the sand pattern of the pump body, the surface finish of the fluid channel is improved by 50%, the efficiency of the pump body is improved from 75% to 82%, and the annual energy consumption is saved by 1.2 million yuan.

4. In the field of art and architecture: oversized bronze sculptures

- Application: 60 meters long bronze sculptureSegmented sand molding(e.g. the "Nine Horses" sculpture in Nanjing);

- Benefits: Eliminates the need for large wood moldings, allows for complex artistic textures, and reduces the sculpture production cycle from 1 year to 3 months.

Fifth, choose the right solution: 3DPTEK "equipment + ecological" integrated services

The success of 4-meter sand 3D printing requires not only high-quality equipment, but also a complete ecological support. 3DPTEK provides "end-to-end" solutions to reduce the difficulty of enterprise transformation:

- Proprietary materialsMore than 30 sand-binder formulations (e.g., low viscosity binder for aluminum alloy casting, high temperature resistant binder for steel casting) ensure casting quality;

- intelligent software: It comes with casting simulation system, which can simulate the flow of metal liquid, cooling contraction, optimize the sand design in advance, and reduce the cost of trial and error;

- Full Process Service: Full process support from CAD modeling, sand printing to post-processing of castings, free operator training (3 days to master the operation of the equipment);

- after-sales service24-hour door-to-door service at home, 5 service centers abroad (Germany, the United States, India, etc.), spare parts arrival cycle ≤ 72 hours, to ensure that the equipment is on throughout the year ≥ 95%.

Future Trends in Large-Scale Sand 3D Printing in 2025: Toward "Bigger and Smarter"

1. Continuing size breakthroughs: 6-10 meter class devices in development

3DPTEK has started the research and development of 6-meter-class sand printer, which can realize the whole printing of "8-meter-long ship propellers" and "10-meter-diameter nuclear power equipment shells" in the future, and completely eliminate the defects of large casting splicing.

2. AI+3D Printing: Realizing Intelligent Control of the Whole Process

Integrated AI system for automated completion:

- Optimization of sand mold design (automatically generate the optimal structure according to the casting material and size);

- Printing process monitoring (real-time adjustment of binder injection volume to avoid sand cracks);

- Quality prediction (AI algorithms predict possible defects in castings and adjust the process in advance).

3. Multi-material composite printing: expanding application boundaries

The future equipment can realize "sand + metal powder" composite printing, printing high-temperature-resistant metal coatings on key parts of the sand mold (e.g., the sprue), adapting toTitanium alloy, ultra-high strength steelRefractory alloy casting, expanding the application in the field of high-end equipment.

Conclusion: 4-meter sand 3D printing opens a new era of large casting manufacturing

For heavy manufacturing enterprises, 4-meter-class large sand casting 3D printer is no longer a "technological novelty", but a "necessity to enhance competitiveness" - it breaks the traditional process of It breaks the size and cycle time limitations of traditional processes, and realizes the triple breakthrough of "large-scale + complexity + low cost".

The commercialization of 3DPTEK-J4000 and other equipment has provided a fast track from design to casting for automotive, aerospace, industrial machinery and other industries. In the future, with the research and development of 6-10 meter-class equipment and the integration of AI technology, large casting manufacturing will enter a new stage of "full digitalization, zero defects and greening", and the enterprises that take the lead in laying out this technology will have an absolute advantage in the market competition.

4 米級大型砂型鑄造 3D 打印機:2025 年解鎖大型鑄件制造,縮短 80% 周期 + 降本方案最先出現在三帝科技股份有限公司。

]]>砂型 3D 打印技術:2025 年重塑金屬鑄造行業,縮短 80% 周期 + 降本方案解析最先出現在三帝科技股份有限公司。

]]>Read navigation

- I. What is Sand 3D Printing? Core Definition + Process Characteristics (different from traditional mold making)

- Second, the foundry must use sand 3D printing 4 core reasons (to solve the industry pain points)

- Three, sand 3D printing principle: 4 steps from design to sand (full process automation)

- Parameters of 3DPTEK Sand 3D Printer (Applicable to Different Industries)

- V. Sand 3D printing 4 major industry application scenarios (with actual cases)

- Why choose 3DPTEK sand 3D printing solution? (4 core competencies)

- VII. Future Trends of Sand 3D Printing in 2025 (3 Directions to Watch)

- VIII. Conclusion: Sand 3D printing is not an "optional technology" but a "must-have transformational tool"

I. What is Sand 3D Printing? Core Definition + Process Characteristics (different from traditional mold making)

Sand 3D printing is based onPrinciples of Additive ManufacturingThis is an industrial technology that directly transforms digital CAD models into solid sand molds / cores. Instead of the traditional "mold-making - sand-turning" process, the sand mold is formed by laying sand layer by layer on the printer and curing it by spraying a binder. The core process isBinder jetting technologyThe J1600Pro, J2500, and J4000 models from 3DPTEK, for example, offer significant advantages over conventional molding:

| comparison dimension | Sand 3D Printing | Traditional mold making process |

| production cycle | 24-48 hours | 2-4 weeks |

| Complex structure realization | Easy printing of internal channels, thin-walled parts | Difficult to realize, need to split multiple sand cores |

| Tooling Costs | No need for physical molds, cost is 0 | Customized wood / metal molding required, high cost |

| Material utilization | 90% or more (uncured sand can be recycled) | 60%-70% (much cutting waste) |

| Design Flexibility | Supports real-time modification of CAD models for fast iteration | Modification of the design requires re-modeling and long lead time |

Second, the foundry must use sand 3D printing 4 core reasons (to solve the industry pain points)

1. Reduced cycle time 80% for fast response to order requirements

While traditional processes take 2-4 weeks to produce complex sand molds (e.g. pump bodies, turbine casings), sand 3D printing takes only 1-2 days. Especially suitable forPrototype molding, small batch customization, emergency spare parts productionScenario -- A foundry uses the 3DPTEK J1600Pro to print sand molds of pump bodies from design to delivery in just 36 hours, a reduction of 80% compared to the traditional process, helping to bring products to market 2 weeks earlier.

2. Breaking through structural limitations and realizing difficult casting

Sand 3D printing eliminates the need for "mold release" issues, making it easy to create designs that would be impossible with traditional processes:

- in the field of aerospaceTurbine blade internal cooling channels(The traditional process requires more than 5 sets of sand cores to be disassembled, which is prone to assembly errors);

- AutomotiveLightweight thin-walled motor housing(Wall thickness can be as low as 2mm, conventional sand type is prone to fracture);

- industrial machineryIntegrated oil passages transmission housing(Reduces post-drilling process and reduces scrap rate).

3. Long-term cost reductions 40%, offsetting equipment input costs

Despite the high initial investment in sand 3D printers, the cost advantage is significant when calculated over the full life cycle:

- Elimination of mold production costs (a set of large metal mold cost more than 100,000 yuan, 3D printing can be completely eliminated);

- Reduced scrap rate (digital design + simulation optimization, casting scrap rate reduced from 15% to less than 5%);

- Reduced labor costs (automated printing eliminates the need for manual assembly of multiple sand cores, reducing labor by 50%).

4. Comply with environmental requirements and realize green production

As global environmental regulations tighten (e.g., the EU REACH standard), sand 3D printing meets the need for environmental protection through two main technologies:

- adoptionLow Emission Binder(3DPTEK proprietary formulation with VOC emissions below industry standard 50%);

- Uncured sand can be 100% recycled, reducing solid waste generation and environmental treatment costs.

Three, sand 3D printing principle: 4 steps from design to sand (full process automation)

Sand 3D printing (binder jetting technology) is a simple, highly automated process that requires no complex human intervention, with the following core steps:

- Digital Design and Simulation: Engineers use CAD software to build sand models, and simulate the flow of liquid metal, cooling and shrinkage processes through the 3DPTEK casting simulation system to optimize the pouring system and riser position of the sand model, so as to avoid defects such as shrinkage holes and porosity in the castings;

- Layer-by-layer molding: The printer automatically lays down 0.26-0.30mm thick sand (quartz sand/chromite sand optional) and then, based on the slicing data, sprays the binder on the area to be cured and builds up the sand pattern layer by layer;

- Curing and sand cleaning: After printing, the sand model is left to cure (strengthen) in a closed environment for 2-4 hours, after which the uncured loose sand (which can be recycled directly) is blown out with compressed air;

- Casting and post-processingThe molten metal (aluminum alloy, steel, copper alloy, etc.) is poured into the sand mold, which is then cooled, cracked and removed for finishing - the entire process requires no human intervention in the sand mold making process.

Parameters of 3DPTEK Sand 3D Printer (Applicable to Different Industries)

3DPTEK, as an industry leader, has introduced several models of sand printers covering small to very large casting needs with the following core parameters:

| models | Print size (L × W × H) | layer thickness | Applicable Scenarios | Suitable for casting alloys |

| 3DPTEK-J1600Pro | 1600×1000×600mm | 0.26-0.30mm | Small and medium-sized sand molds (e.g., motor housings, small pump bodies) | Aluminum, cast iron |

| 3DPTEK-J2500 | 2500×1500×800mm | 0.26-0.30mm | Medium to large sand molds (e.g. gearbox housings, turbine housings) | Steel, copper alloys |

| 3DPTEK-J4000 | 4000×2000×1000mm | 0.28-0.32mm | Oversized sand molds (e.g. ship propellers, large valves) | Stainless steel, specialty alloys |

Core AdvantagesAll models support "sand + binder" custom formulations, and 3DPTEK has over 30 proprietary formulations to match the needs of different alloys (e.g., aluminum alloy casting for low-viscosity binder, steel casting for high-temperature-resistant sand).

V. Sand 3D printing 4 major industry application scenarios (with actual cases)

1. The automotive sector: core support for the electrification transition

- Application Scenarios:Electric vehicle water-cooled motor housing, lightweight battery tray sand molding.;

- Example: A commercial electric truck manufacturer used the 3DPTEK J2500 to print a sand mold of the motor case, realizing an "integrated cooling channel" design, which improved the motor cooling efficiency by 30%, while reducing the weight of the case by 25% and increasing the range by 50km.

2. Aerospace industry: high-precision casting of complex parts

- Application Scenarios:Turbine blades, aero-engine combustion chamber sand molding.;

- Advantage: The dimensional accuracy of the sand mold reaches CT7 level, which meets the requirement of "zero error" for aerospace parts, and at the same time, avoids the scrapping of blades caused by the assembly error of traditional sand cores.

3. Industrial machinery industry: core components for large equipment

- Application Scenarios:Sand molding of large pumps and compressor housings.;

- Case: A heavy industry enterprise used 3DPTEK J4000 to print a 4-meter-long pump body sand mold, the traditional process requires the production of three sets of metal molds (costing more than 300,000 yuan), 3D printing directly eliminates the cost of molds, and shortens the production cycle from 4 weeks to 3 days.

4. Energy and marine industry: manufacture of very large castings

- Application Scenarios:Ship propeller, wind turbine shell sand molding.;

- Advantage: The J4000 model's 4-meter wide print size allows for the printing of very large sand molds in one pass, eliminating the need for splicing and reducing mold-fitting defects in castings.

Why choose 3DPTEK sand 3D printing solution? (4 core competencies)

1. Full-scene equipment coverage, adapting to different capacity needs

From 1.6-meter compact machines (J1600Pro) to 4-meter ultra-large machines (J4000) forSmall batch trial production to large scale mass productionThe J1600Pro is available for small and medium-sized foundries with a capacity of 5-8 sand molds per day, and the J4000 is available for large foundries with a capacity of 2-3 oversized sand molds per day.

2. Proprietary material formulas to ensure casting quality

3DPTEK has more than 30granule – Exclusive formulation for bonding agents, optimized for different alloys:

- Aluminum alloy casting: low viscosity binder, good sand permeability, reduce casting porosity;

- Steel casting: high-strength binder, sand mold high temperature resistance (more than 1500 ℃), to avoid the defect of sand washing;

- Copper alloy casting: low ash binder to prevent inclusions on the casting surface.

3. Integrated technical support to reduce the difficulty of transition

Provide "equipment + software + service" full-process support:

- free of chargeCasting Simulation Software(Optimize sand design and reduce trial and error costs);

- Inside the casting technology center, can assist customers in sand testing, casting process debugging;

- Provide operator training (1 to 1 instruction to ensure equipment operation within 3 days).

4. Global after-sales network to ensure production stability

The equipment has been landed in more than 20 countries in Europe, Asia, the Middle East, etc., and the after-sales response speed is fast:

- Domestic 24-hour door-to-door service (48 hours for remote areas);

- 5 service centers abroad (Germany, India, USA, etc.) for quick replacement of spare parts;

- Free equipment maintenance 2 times a year to extend the life of the equipment (average life of more than 8 years).

VII. Future Trends of Sand 3D Printing in 2025 (3 Directions to Watch)

1. AI+3D Printing for Zero Defect Casting

The future of sand 3D printing will be integratedAI Design Optimization System-- Input casting parameters (material, size, performance requirements), AI can automatically generate the optimal sand structure, while real-time monitoring of the printing process, by adjusting the amount of binder injection, sand laying thickness, to avoid cracks, uneven density and other problems in the sand, to achieve "zero defects " production.

2. Closed-loop sand recycling, material utilization rate of 98%

exploit (a resource)Automatic Sand Recovery SystemIn addition, the uncured sand and old sand will be screened, decontaminated and recycled, and the material utilization rate will be increased from the current 90% to more than 98%, which further reduces the material cost and meets the requirements of the "Double Carbon" policy.

3. Multi-material composite printing to expand application boundaries

The future of sand 3D printers will enable "sand + metal powder" composite printing - printing metal coatings on critical parts of the sand model (e.g., gates) to improve the sand model's high-temperature resistance, and to accommodateUltra-high strength steel, titanium alloyRefractory alloys such as casting, expanding the application in the field of aerospace, high-end equipment.

VIII. Conclusion: Sand 3D printing is not an "optional technology" but a "must-have transformational tool"

In the increasingly competitive metal casting industry, "fast response, complex structure, green cost reduction" has become the core competitiveness - sand 3D printing by shortening the cycle time of 80%, realizing difficult designs, long-term cost reduction 40% and help foundries break through traditional process constraints.

3DPTEK, as a leading company in the field of sand 3D printing, provides customized solutions for foundries of different sizes through multiple models of equipment, exclusive material formulations, and integrated technical support. Whether in the automotive, aerospace, industrial machinery or energy sectors, choosing sand 3D printing means choosing the double advantage of "cost reduction and efficiency + technological leadership", which is also the core way for foundries to survive in 2025 and beyond.

砂型 3D 打印技術:2025 年重塑金屬鑄造行業,縮短 80% 周期 + 降本方案解析最先出現在三帝科技股份有限公司。

]]>工業級 SLS 3D 打印機:復雜零件精密制造的革新方案,2025 年技術解析與行業應用最先出現在三帝科技股份有限公司。

]]>Read navigation

- I. What is an Industrial Grade SLS 3D Printer? Core Definition and Technical Characteristics

- 4 Core Benefits for Manufacturers Choosing Industrial SLS 3D Printing

- Third, the core material of industrial-grade SLS 3D printing: more than nylon, casting application materials into a new hot spot

- Industrial-grade SLS 3D printing works: from design to finished product in 5 steps

- V. Industrial SLS 3D Printer Industry Applications: Typical Scenarios in 4 Major Fields

- Case Study: European Automotive Supplier Uses SLS 3D Printing to Reduce Cost by 40% and Increase Efficiency by 70%

- 3DPTEK Industrial Grade SLS 3D Printer: Why is it the Industry's Preferred Choice?

- VIII. Future Trends of Industrial SLS 3D Printing in 2025: 3 Directions of Concern

- IX. Conclusion: Industrial Grade SLS 3D Printing, More Than a "Printer", It's a Tool for Manufacturing Innovation

I. What is an Industrial Grade SLS 3D Printer? Core Definition and Technical Characteristics

Industrial-grade SLS 3D printers use a high-powered laser toNylon, composite polymers, specialty casting sands/waxesThe industrial-grade equipment for selective fusion of powder materials and other materials to build up solid 3D parts layer by layer. Its core technical characteristics are significantly different from desktop-level SLS equipment:

| comparison dimension | Industrial Grade SLS 3D Printer | Desktop SLS Devices |

|---|---|---|

| Molding space | Large (some models up to 1000mm) | few |

| production efficiency | High, supports mass production | Low, mostly single-piece printing |

| Quality of parts | Stable and meets mass production standards | Lower precision, suitable for prototyping |

| Material compatibility | Hiro (engineering plastics, casting sand, wax) | Narrow (mostly basic nylon powder) |

In addition, industrial-grade SLS printing requires no support structure (unsintered powder naturally supports the part), making it easy to accomplish things that are impossible with traditional processes.Complex internal channels, lightweight lattice structures, active componentsAll-in-one molding.

4 Core Benefits for Manufacturers Choosing Industrial SLS 3D Printing

In the aerospace, automotive, medical, foundry and other fields, industrial-grade SLS technology has become the key to improve productivity and innovation, the core advantages are reflected in the following four points:

1. No upper limit of design freedom, breaking through the traditional process limitations

No support structure is required, allowing engineers to designComplex internal cavities, integrated moving parts, topology-optimized lightweight structure-- such as hollow structural parts in aerospace and complex runner components in automotive engines -- are difficult to achieve with traditional processes such as CNC machining and injection molding.

2. Strength of parts up to standard, directly used in mass production scenarios

SLS printed parts are not "prototypes" but finished parts with useful functionality. Commonly usedPA12 (nylon 12), PA11 (nylon 11), glass fiber reinforced nylonThese materials have mechanical properties close to those of injection-molded parts, as well as excellent chemical resistance and impact resistance, and can be used directly in mass-production scenarios such as automotive interior parts and medical and surgical tools.

3. Reduced production lead time 70%, rapid response to market demand

From CAD model to finished part, industrial-grade SLS prints in3-7 daysThis is much faster than traditional mold making, which typically takes weeks. For R&D teams in prototype validation, small batch customized production, and emergency spare parts replenishment, this advantage can dramatically shorten the time-to-market cycle and seize the market opportunity.

4. Supporting scale-up and transition production to reduce costs

Industrial-grade SLS equipment can nest dozens or even hundreds of parts in a single print run, making it ideal forSmall batch mass productionSLS can also be used as a "bridge manufacturing" tool - using SLS to quickly produce transitional parts before committing to expensive injection molds, avoiding risky tooling investments and reducing upfront production costs.

Third, the core material of industrial-grade SLS 3D printing: more than nylon, casting application materials into a new hot spot

Nylon is the first material that comes to mind when you think of SLS materials, but industrial-grade equipment has achieved multi-material compatibility and specialized materials, especially in the foundry sector, are driving the digital transformation of traditional casting processes:

1. Foundry sand: direct production of metal casting sand molds / cores

by combiningQuartz Sand / Ceramic SandMixed with a special binder for laser sintering, industrial-grade SLS printers can directly print sand molds and cores for metal casting, with core benefits including:

- Suitable for pump bodies, turbine housings, automobile engine blocks, etc.Complex internal cavity castings.;

- Eliminates the need for traditional wood/metal molds, reducing mold costs and lead times;

- High precision of sand size (error ≤0.1mm), smooth surface, improve the yield of castings.

2. Casting wax: efficient production of wax molds for investment casting

Industrial grade SLS devices can printLow ash casting waxIt is used for investment casting of aviation turbine blades, jewelry, and precision hardware, as opposed to traditional CNC machining of wax molds:

- Low surface roughness (Ra≤1.6μm) to meet the needs of precision parts casting;

- Ash content <0.1%, no residue when casting dewaxing, avoid casting defects;

- Shortened production cycle time 50% for rapid production of small quantities of precision wax molds.

3DPTEK Industrial SLS Casting Equipment Recommendation

As a leading brand in the industry, 3DPTEK offers specialized models for foundry scenarios, adapted to the needs of industrial-grade production:

- SLS Sand 3D PrinterThe molding length is up to 1000mm, which supports the mass production of large-size casting sand molds and is suitable for casting of large mechanical parts;

- SLS Wax Mold 3D Printer: High-resolution printing (layer thickness 0.08mm), compatible with standard casting wax formulations for seamless integration into traditional investment casting processes.

Industrial-grade SLS 3D printing works: from design to finished product in 5 steps

The industrial-grade SLS print process is highly automated, with a 5-step core process that eliminates the need for complex manual intervention:

- 3D design and pre-processing: Completion of the part design in CAD software, optimization of the structure (e.g., increase of wall thickness, nesting arrangement) by means of special software, and generation of STL files that are recognized by the SLS equipment;

- Powder laying: The equipment automatically spreads the powder material evenly on the molding platform, and the layer thickness is controlled at0.08-0.35mm(precision adjustable);

- Selective Laser Sintering: High-power laser scanning based on the cross-section trajectory of the part fuses and solidifies the powder particles to form a single-layer part structure;

- pile up layer by layer: The molding platform is lowered one level, the machine is re-laid with new powder, and the laser sintering step is repeated until the part is fully formed;

- Cooling & Powdering: The parts are cooled slowly in a closed environment (to avoid deformation), and the unsintered powder is removed after cooling (recyclable, with a material utilization rate of more than 90%).

V. Industrial SLS 3D Printer Industry Applications: Typical Scenarios in 4 Major Fields

With the advantages of high precision, high compatibility and fast production, industrial-grade SLS technology has landed in many key industries, and the typical application scenarios are as follows:

1. Aerospace: combining light weight with high reliability

- give birth to a childLightweight ducting, air handling componentsThe weight of the part is reduced 30%-50% through lattice structure optimization, while strength is guaranteed;

- Manufacturing of complex structural satellite components, aircraft interior mounts without assembly, reducing the risk of failure.

2. Automotive: rapid prototyping combined with low-volume mass production