北京三帝科技股份有限公司(3D Printing Technology, Inc.)是一家專注于工業(yè)級增材制造(3D打印)裝備與快速制造服務的國家級高新技術企業(yè)、專精特新“小巨人”企業(yè)。獲金科君創(chuàng)、中金資本、中科海創(chuàng)、成為資本、北京市新材料基金、國機基金等多家機構投資。以降本、提效、提質為目標,構建了覆蓋3D打印裝備與材料的研發(fā)生產、工藝技術支持及快速成品制造的完整產業(yè)鏈。

公司總部位于北京,在全國設有多家子公司,擁有超過12萬平方米的場地(其中自持面積超6萬平方米),建立了全鏈路、多材料、全尺寸的國內快速制造交付體系及國際服務網絡,業(yè)務覆蓋全球30多個國家和地區(qū)。

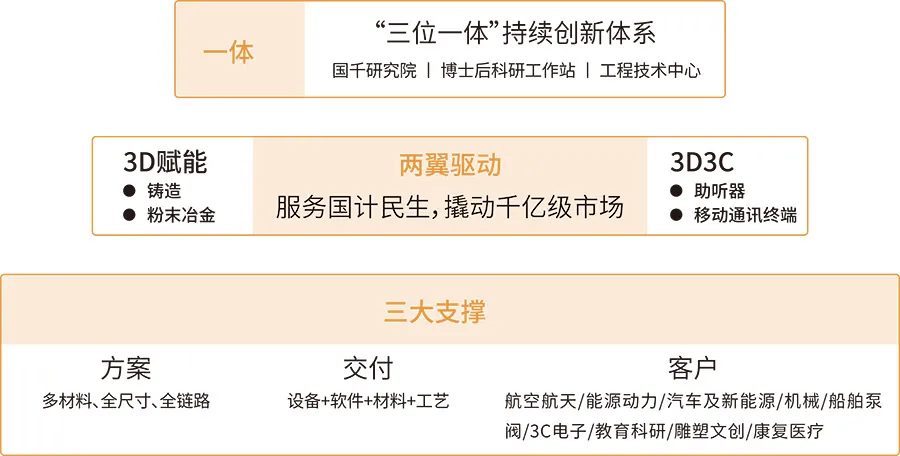

三帝科技技術底蘊深厚,旗下隆源成型1994年即成功研制出國內第一臺商品化工業(yè)級3D打印機。公司是國內唯一一家同時掌握選擇性激光燒結(SLS)、選擇性激光熔化(SLM)、砂型3D打印(3DP)和粘結劑噴射(BJ)四項核心3D打印技術的服務商。公司創(chuàng)新體系采用“三位一體”結構,包括:“國千科技研究院”——匯聚40余位國家級專家和博導,專注于原始創(chuàng)新;博士后科研工作站——致力于共性技術開發(fā);以及企業(yè)研發(fā)團隊——負責技術成果轉化。公司已牽頭或參與完成6項科技部重大專項,累計申報知識產權近300項,其中授權發(fā)明專利59項。

通過并購整合與自建,三帝科技已在中國布局8個3D打印快速制造基地,形成生態(tài)網絡。基于“工藝設計-3D打印-鑄造-機加工-檢測”一體化流程,公司為客戶提供快速試制、小批量多品種及復雜金屬件制造服務。依托自主研發(fā)的3DP砂型打印和SLS砂型/蠟型打印系列裝備,提供3DP砂鑄、SLS砂鑄、SLS精鑄等全套解決方案,服務涵蓋航空航天、電力能源、船舶泵閥、汽車、軌道交通、工業(yè)機械等領域的500余家客戶,材料覆蓋鋁、銅、鐵、鋼、鎂、高溫合金、鈦合金等。

依托BJ技術“高效率、低成本、無熱應力”的優(yōu)勢及深厚技術儲備(包括開發(fā)出高性能粘結劑體系及20余種工藝配方),三帝科技在散熱領域實現(xiàn)突破。通過材料配方優(yōu)化、三維結構構建及精密的后處理工藝(脫脂燒結控形控性),公司實現(xiàn)了多種材料及復合材料(如銅-金剛石、銅-碳化硅)的高質量成型,產品性能優(yōu)于MIM國際標準。公司實施差異化設備策略:面向科研機構與芯片設計企業(yè),提供科研級設備3DPTEK-J160R,用于快速原型制造與熱設計驗證;面向液冷服務器制造商,提供集成化工業(yè)方案(3DPTEK-J400P/J800P設備+專用粉末/粘結劑+工藝包),可縮短客戶工藝開發(fā)周期60%以上。

三帝科技以3D打印技術賦能康復醫(yī)療,提供助聽器、數(shù)字化口腔(含義齒)、矯形器、假肢等產品及服務,并擁有國內首個3D打印鈦合金助聽器醫(yī)療器械注冊證。通過并購深圳雙龍齒研(持有歐盟CE、美國FDA及中國二類醫(yī)療器械認證,產品銷往全球30多國),公司進一步完善高端定制化數(shù)字化口腔解決方案,服務全球診所與種植中心。

三帝科技及旗下企業(yè)已通過ISO 9001質量管理體系、ISO 13485醫(yī)療器械質量管理體系、ISO 45001職業(yè)健康安全管理體系、ISO 14001環(huán)境管理體系、綠色供應鏈管理體系、CE、EAC等認證,并獲得一類和二類醫(yī)療器械準入資格認定。公司參與起草了多個國家及行業(yè)標準,其中3項國家標準已發(fā)布。榮獲工信部首批“增材制造優(yōu)質供應商”、“增材制造典型應用場景供應商”、“中國高新技術成果暨新產品交易博覽會金獎”、“北京市科學技術獎二等獎”、“廣西省科技進步獎二等獎”、“中國有色金屬工業(yè)科學技術獎二等獎”、“機械工業(yè)科學技術獎二等獎”、“全球鑄造行業(yè)創(chuàng)新技術與產品”、“全國鑄造裝備創(chuàng)新獎”等多項榮譽。

Relying on the "Trinity" continuous innovation system, the company is driven by the two wings of "3D Empowerment" and "3D3C", and realizes the sustainable and steady development of the company through the three major supports of "Solution + Delivery + Customer". + customer" three major support, to realize the company's sustained and steady development.

Xianyang 3D Casting Center covers an area of 22,000 square meters, with an existing building area of 18,000 square meters. It has more than 50 sets of advanced casting and processing equipment. Including 3DP sand printing equipment, SLS selective laser sintering 3D printing equipment and advanced modeling and testing equipment such as CMM, laser 3D scanner, vacuum direct reading spectrometer, etc., with an annual production capacity of about 1,800 tons of castings. Through sand casting, low-pressure casting, precision casting, metal-type casting and other professional casting processes, we provide small-lot rapid trial production of aluminum alloy, copper alloy, wear-resistant copper bushings, tin bronze, aluminum bronze, cast iron, cast steel and other castings.

Daiming 3D Smart Manufacturing Center covers an area of 70 acres, with a total construction area of 24,614 square meters. With independent intellectual property rights of 3D casting printing equipment, aluminum alloy casting production line, machining and testing equipment, with "process design + 3D printing + casting + machining and testing" integrated service capabilities, the establishment of 3D printing intelligent casting, liquid extrusion casting, low-pressure casting, differential pressure casting, gravity casting and other automation, Intelligent production line, can achieve an annual output of 20,000 tons of intelligent manufacturing of high-end aluminum alloy parts.

Henan Pingdingshan 3D Casting Center, covering an area of 180 acres, with a total construction area of 40,000 square meters, has independent intellectual property rights of 3D casting printing equipment, aluminum alloy casting production line, machining and testing equipment, painting, baking and environmental protection treatment equipment, the daily painting capacity of up to 200 square meters, the implementation of the national standard, enterprise standard standards and other standards. With the integrated service capability of "process design + 3D printing + casting + machining and testing", the company has set up automated and intelligent production lines for 3D printing intelligent casting, low-pressure casting, gravity casting, precision casting, etc., and possesses the research and development and manufacturing capability of super-large and shaped aluminum alloy castings, and can achieve an annual output of 5,000 tons of intelligently manufactured high-end aluminum alloy parts. Aluminum alloy parts with an annual output of 5,000 tons.

Yulin 3D Casting Center can provide 3DP sand printing rapid iron casting and aluminum casting services, based on the Guangdong-Hong Kong-Macao Greater Bay Area and the Beibu Gulf Economic Zone key corridor, radiating South China and ASEAN hundreds of billions of machinery manufacturing market, with an annual production capacity of 2 million pieces of high-performance aluminum alloy products.

Rizhao 3D Casting Center has SLM, SLS, 3DP, BJ and other 3D printers, lathes, boring machines, milling machines, CNC machining centers and other processing equipment, and a number of intelligent casting production line. Provide sand casting, precision casting and other rapid manufacturing services. Using laser SLM/SLS, inkjet BJ, light-curing SLA and other additive manufacturing technologies, combined with casting, CNC machining, surface treatment, heat treatment, non-destructive testing and other processes, to provide one-stop prototype prototype verification of aluminum alloys, copper alloys, stainless steel, cast iron and other one-stop sample, small and medium batch flexible manufacturing, manufacturing services for complex cavities and structures.

Tongling 3D Casting Center covers an area of 7,000 square meters, with domestic advanced level of investment casting, resin sand casting, gypsum casting, bronze forging and all kinds of metal art processing technology, with 3DP sand printing intelligent casting, liquid extrusion and low-pressure casting of high-performance aluminum alloys, copper alloys casting capacity.

Meet user needs and exceed service expectations;

Help employees grow and develop outstanding talent;

Respect for shareholders' rights and protection of investment interests;

Promote the development of the industry and return to the public;

Continuous development of enterprises, casting a hundred years of brand.

Address:No.7 Jin Yi Street, Shunyi District, Beijing, China

Tel: 010-62117806

E-mail: [email protected]